FreshByte lot traceability enables a swift, accurate identification of affected products, allowing businesses to act quickly.

FreshByte Lot Traceability

Lot traceability is a critical process that ensures full visibility and control over products as they move through the supply chain, from raw materials to the final customer. It allows businesses to trace a product’s history quickly, ensuring any issues—such as defects, contamination, or recalls—can be addressed promptly and efficiently.

This system assigns a unique lot number to each batch or production run, documenting key details at each step of the process. These include supplier information, production dates, quality checks, shipping details, and customer invoices. By doing so, lot traceability eliminates guesswork, minimizes risks, and enhances product safety.

In the event of a recall, lot traceability enables a swift, accurate identification of affected products, allowing businesses to act quickly. Whether tracing products forward through the supply chain or backward to customers or vendors, FreshByte helps maintain compliance with industry regulations, improves transparency, and ensures the highest standards of quality and safety.

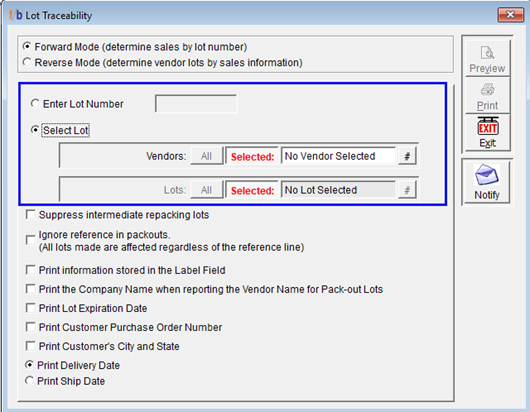

Traceability Forward Mode

Inventory -> Inventory Reports -> Lot Traceability

By default, the system opens in Forward Mode, which allows the user to trace an inventory item from its origin (vendor/lot) through internal processing and/or distribution to customers.

The user can scan initiate a search in one of the following ways:

- Enter a Lot Number: Directly trace a specific lot by entering complete lot number. The user must enter the entire lot number.

- ‘Select Lot’ Option: Provides a dropdown to search by Vendor and lot number.

The user can click (#) next to Vendors to display the Vendor Lookup. The user can then select () next to Lots to display a lookup of all associated lots sold by the vendor, the date range, item information, received dates, and Vendor lot numbers.

- Reviewing and Printing Results:

- Once a vendor and/or lot is selected, the system displays a full breakdown of the lot’s usage and movement.

- This includes any Processing, Repacking, or Distribution.

- The user can then choose to print the traceability report for fast reference during audits, recalls, or internal quality reviews.

- The system will display all consumption of the item and/or the Customer information, invoice number and contact information.

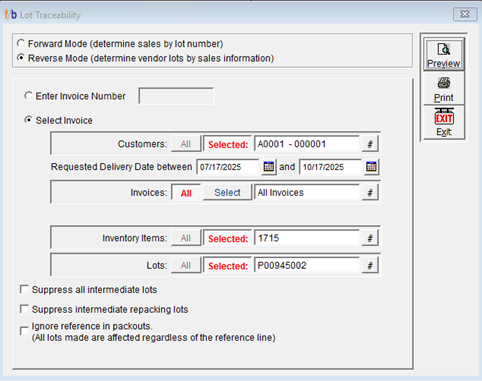

Traceability Reverse Mode

Inventory -> Inventory Reports -> Lot Traceability

The Traceability Reverse mode function allows users to trace an inventory item starting from the Sales Information, enabling efficient tracking for audits, recalls, or quality control.

The user can scan initiate a search in one of the following ways:

- Select Invoice Number: Directly trace an Invoice number to origin by entering a Sales Invoice Number to trace the specific lot(s) associated with that sale.

- Select Invoice Option: Click the ‘Select Invoice’ Radio Button to search using multiple criteria:

- Customer

- Date Range

- Invoice Number Lookup

- Inventory Item Lookup

Customer Lookup

- Click the (#) icon next to Customer to open the Customer Lookup window.

- Optionally, apply a calendar date range filter to narrow results to specific delivery dates.

Invoice Lookup

- Click the (#) icon next to Invoice to display all invoices associated with the selected customer.

Inventory Item Lookup

- Click the (#) icon next to Inventory Items to view all items sold to the selected customer.

Reviewing Traceability Results

Once the Invoice, Customer, and/or Item are selected:

- The system displays a full traceability breakdown of the lot’s origin, including:

Processing details

- Repacking history

- The results also include:

- Originating Vendor Information

- Purchase Order Number

- Date Received

- Quantity Received

Printing the Traceability Report

- After reviewing the traceability results, users can print the report for:

- Regulatory or third-party audits

- Product recall investigations

- Internal quality assurance reviews